Utility Management System

Lucky Textile Mills Unit 06

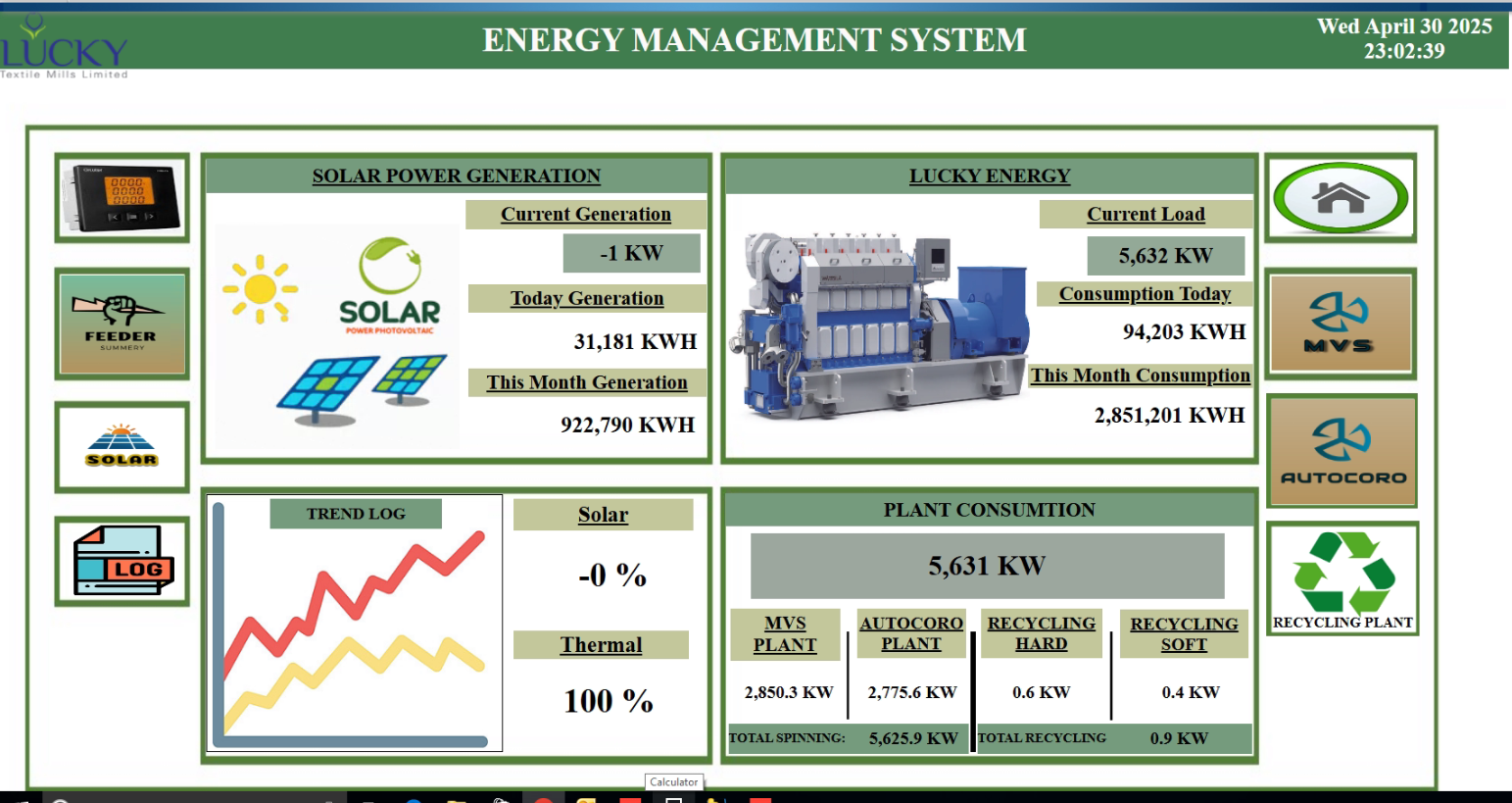

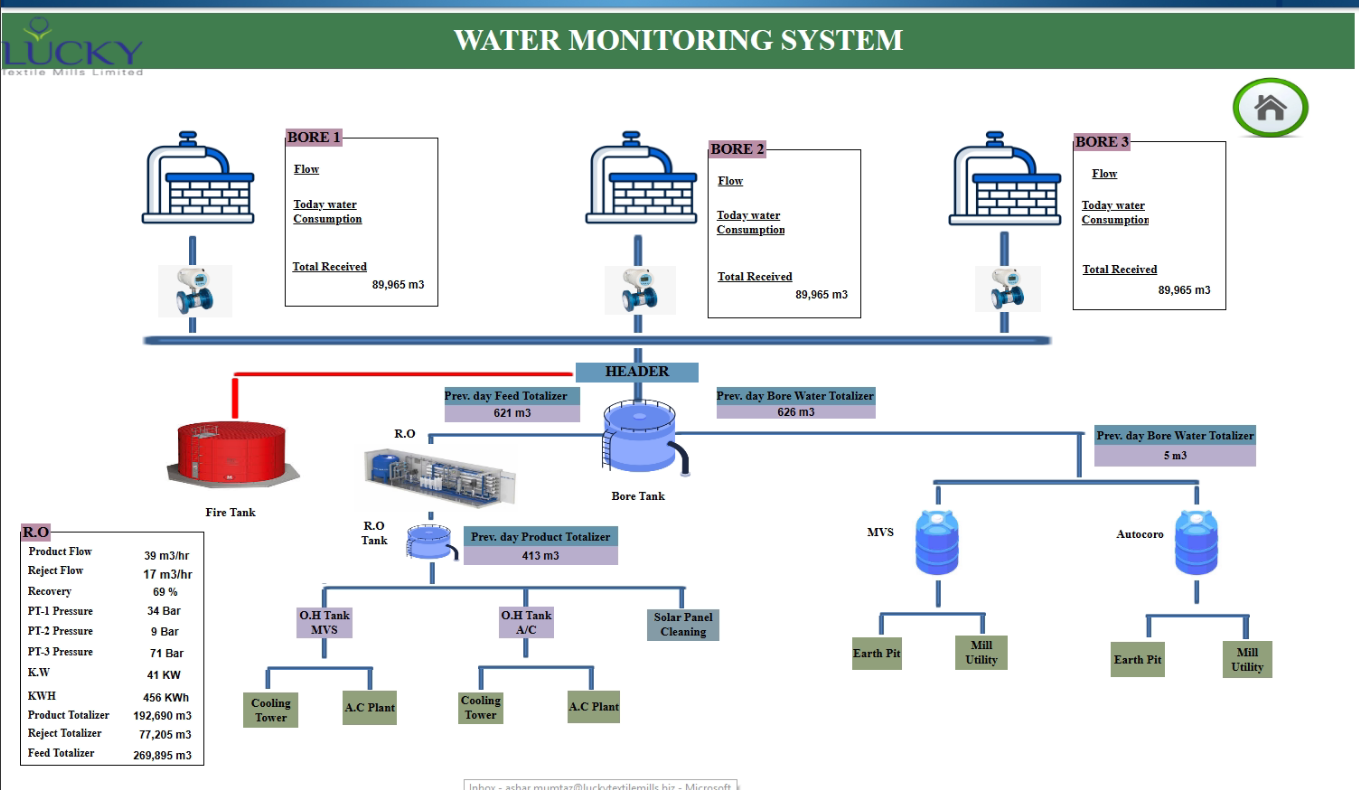

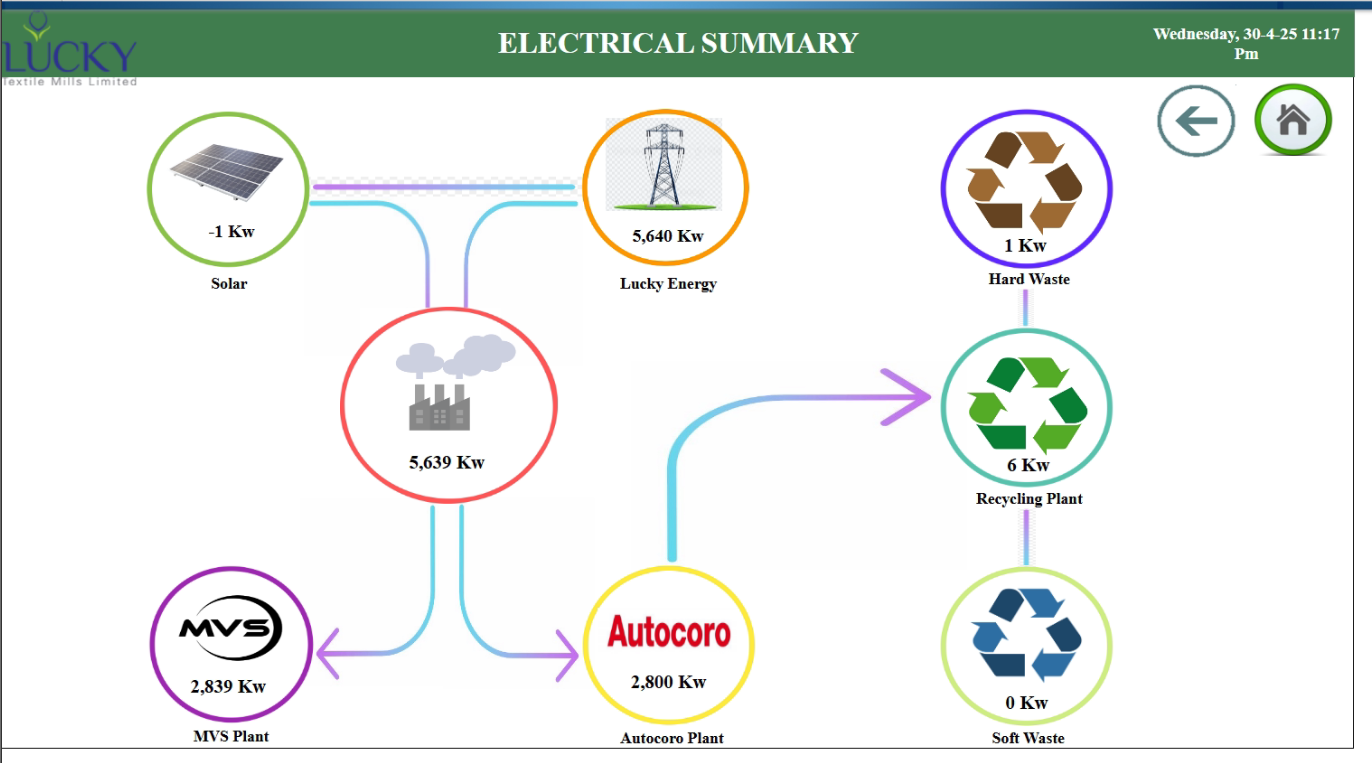

The objective was to implement a comprehensive Utility Management System (UMS) to monitor, analyse, and optimize the consumption of all key utilities at the facility. This project involved the installation of 200 meters to track energy, water, steam, gas, and solar power, providing a holistic view of resource usage and efficiency.

Execution and Outcome

The project involved the strategic installation of 200 meters at various points within the spinning facility to measure and track the consumption of multiple utilities:

Energy: Monitoring electricity consumption from the grid, as well as the output of the on-site solar power system. This provided a clear picture of the mill's total power usage and the contribution of renewable energy.

Water: Meters were placed to track water usage in RO Plant systems, which is for maintaining the right atmospheric conditions for yarn production, as well as other processes

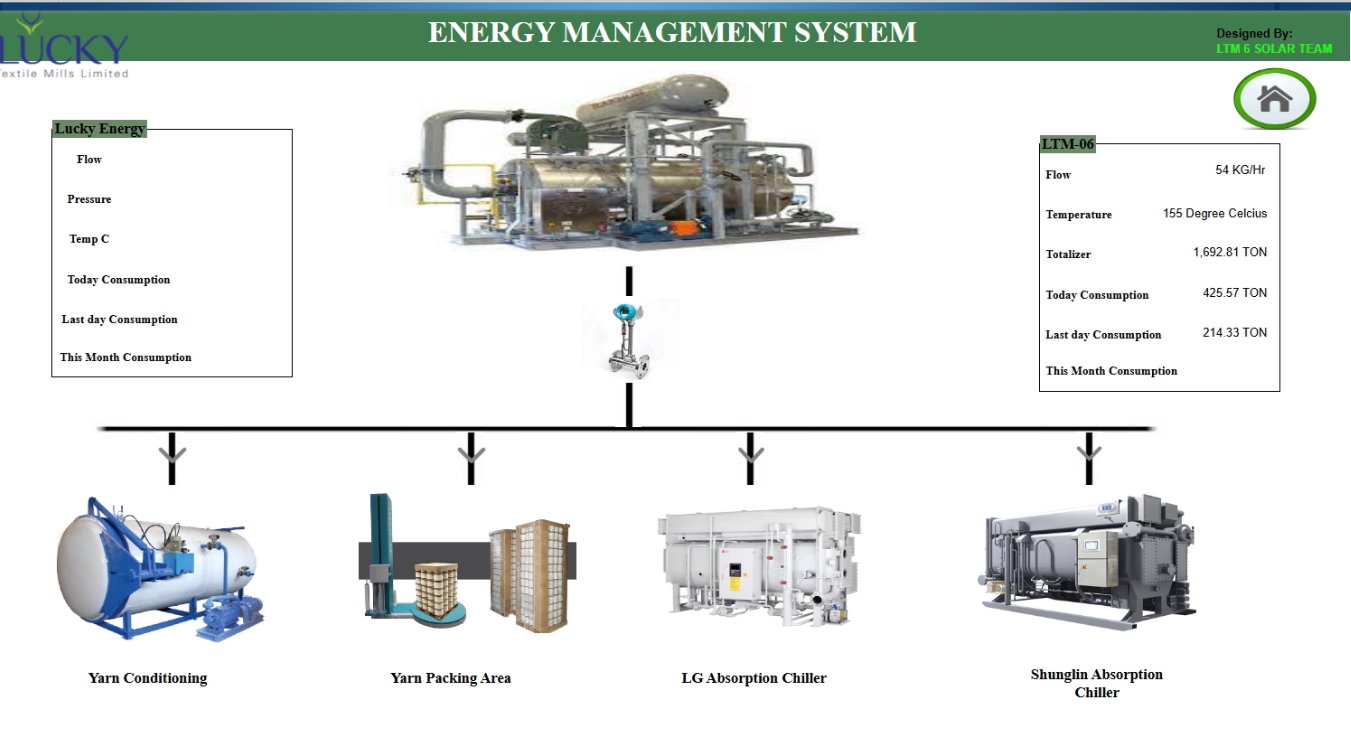

Steam & Gas: These meters provided data on the consumption of All Steam & Gas.

Solar: The system was configured to specifically monitor the power generated from the solar installation, allowing the client to measure its effectiveness and the savings it provides. All the data from these 200 meters was integrated into a centralized UMS platform. This platform provided real-time dashboards and detailed reports, enabling the Lucky Textile Mills team to analyse usage patterns, identify peak consumption periods, and detect any potential leaks or inefficiencies in a timely manner. The ability to cross-reference data (e.g., correlating high energy consumption with specific machine operations or ambient humidity) provided deeper insights into the spinning process.