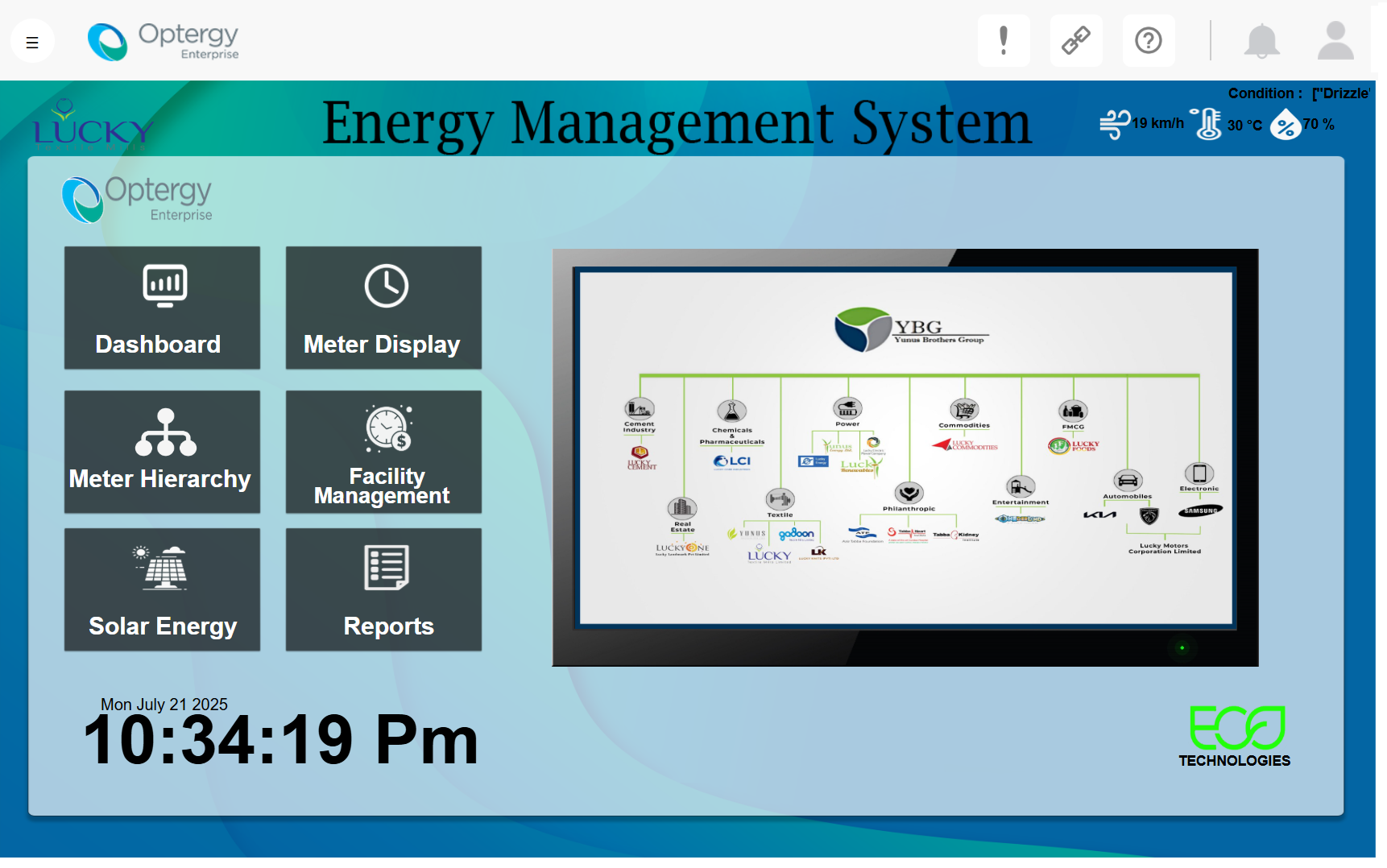

Energy Management System

Lucky Textile Mills Head Office Karachi

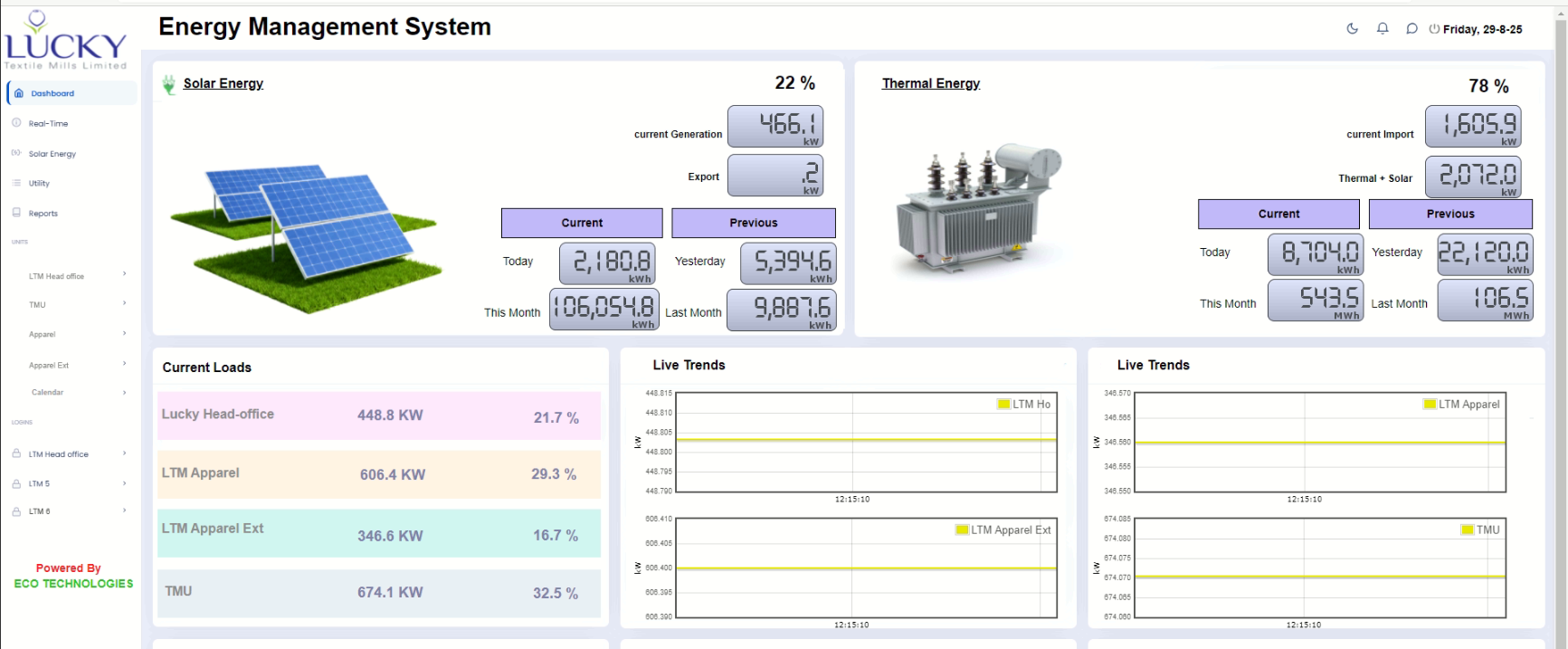

The primary objective of this multi-site project was to establish a centralized energy monitoring and management system across three distinct locations: the Head Office, the Apparel Unit, and the TMU Unit. This comprehensive initiative involved the installation of 150 energy meters and the integration of solar power generation data to provide a complete, holistic view of energy consumption and production across the organization.

This was a significant project spanning multiple Lucky Textile Mills facilities. The project was executed as follows:

Installation of 150 Energy Meters: A total of 150 energy meters were strategically installed across the three sites. These meters were placed on main feeders, sub-panels, and individual machines and systems within the Head Office (for general building loads), the Apparel Unit (for sewing machines, cutting equipment, and finishing processes), and the TMU Unit (for textile processing machinery).

Solar Data Integration: The system was configured to pull real-time generation data from the existing or new solar power installations at the sites. This provided crucial insight into the contribution of renewable energy, allowing the client to measure the effectiveness of their green initiatives.

Centralized Monitoring Platform: All data from the 150 meters and the solar systems was aggregated into a single, centralized platform. This gave management a consolidated view of energy usage across all three locations, enabling them to compare consumption patterns, identify best practices, and allocate resources more efficiently.

The successful implementation provided Lucky Textile Mills with an unprecedented level of visibility into its energy consumption and generation, laying the groundwork for a data-driven approach to energy management.

Key Benifits

Group-Wide Energy Visibility: The centralized system provided a unified dashboard to monitor and analyze energy consumption across multiple units, facilitating corporate-level energy strategy and reporting.

Cost Optimization: By identifying energy-intensive processes and equipment at each location, the client was able to implement targeted efficiency measures, leading to significant reductions in electricity bills. The ability to track solar contribution also allowed them to accurately measure and report on the return on their renewable energy investment.

Enhanced Sustainability Profile: The project provided concrete, auditable data to support the company's commitment to sustainability and environmental goals, which is critical for their brand image and for meeting the requirements of international certifications and standards.

Improved Operations: The real-time data enabled the identification of operational inefficiencies and helped in scheduling maintenance, leading to reduced downtime and a more streamlined production process.